How do you Determine if your Corona Treater Power Supply is Working Correctly?

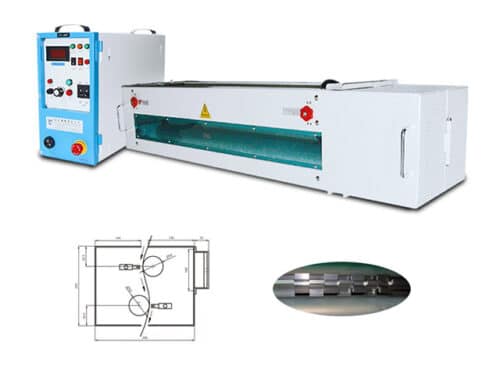

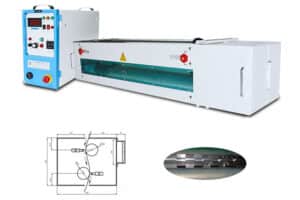

Leave a CommentThe corona treater power supplies that ISI provides are known for being highly reliable, easy to maintain, and low cost. These power supplies are extremely versatile in handling all kinds of corona treaters; Corona Plasma Treaters, Corona Treaters for Blown Film, Corona Treaters for Printing, and Corona Treaters for Sheet and Thick Film.

The newest power supplies installed on the Corona Treaters feature our 4th generation digital control with touch screen controls. The touch screen interface is convenient for adjustments and enables the integration of numerous production-enhancing options. Consult with ISI to determine which power supply and feature set is best for your operation.

See photo examples below of 4th Generation Power Supplies with Touch Screen Control.

The video shown below describes a check procedure of an older 2nd generation power supply for a Chaang Horng Corona Treater.

What is TURRET WINDER?

Leave a CommentWhat is TURRET WINDER?

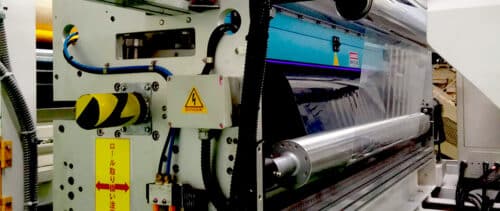

The turret winder is designed for in-line continuous operations with flying roll change, and normally consists of several rewind rollers, which is ideal for converting operation. When the machine processes, the operator can unload wound rolls and reload new core for next processing cycle, which is able to efficiently reducing downtime and increasing throughput in a converting operation.

High Quality Turret Winder Recommendation

Turret Winder offer an efficient method for producing consistent high quality rolls in size as customer asked, moreover, precise tension control is highly essential for turret winder, which can result in perfect edge profile and roll construction via roll buildup process,

High Quality Turret Winder Provider America-Integrated Solution Co.

The Dual Turret Winder 972d and Single Turret Winder we provide are capital investment that guarantees you Quality and Reliability, With our advance technology, our turret winder is able to improve the processing efficiency as well as lower scrap rates and downtime, which leads a greater output.

>>Click for Inquire High Quality Turret Winder for Saving Your Money Now

Selecting the Right Corona Treatment Equipment

Leave a CommentCorona Treatment Equipment problems

Many corona treaters break electrodes, burn up the shrouding, fail roll coatings and more. You may find the corona treatment equipment you being use is hard to treat material or is poor for adhesion, in worse situation, it might spend lots of your time on maintaining or repairing. this is the reason you should talk to us, ISI has extensive background of plastic processing machinery, especially the Corona treaters, Plasma Treater and turret winder.

The Most Trustworthy Corona Treater Supplier in America

Integrated Solution provides a complete line of corona treatment equipment such as, Corona Treater for Blown Film Machine, Corona Treater for Printing, Two Side Corona Treater, One Side Corona Treater, High Speed Corona Treater, Width Corona Treater,Corona Treater for Sheet,Corona Treater for Narrow Web, and we also can offer the customized corona treater as you need.

If you have any problem, we will be more than happy to consult with you and provide straightforward solutions and answers to all of your concern on corona treatment equipment.

Poor Adhesion of Corona Treater

Leave a Comment

What is Corona Treatment

Corona treatment (sometimes referred to as air plasma) is a surface modification technique that uses a low temperature corona discharge plasma to impart changes in the properties of a surface. In order words, Corona Treater is an equipment which be used for surface pre-treatment, however, the effects of corona treatment diminish over time. Therefore many surfaces will require a second “bump” treatment at the time they are converted to ensure bonding with printing inks, coatings, and adhesives.

The Difficulty Of Writing Or Printing On Plastic Film Is Well Known

As you already known, printing on plastic film is difficult process. Imaging that you want write something on a plastic bag with a pen, but the ink doesn’t stick to the surface due to the untreated plastic has a structure and this makes for poor adhesion. Corona treatment is the solution to this well known problem

Fight Against On The Poor Adhesion of Corona Treater

A well designed Corona treatment equipment is able to provide sufficient wetting and adhesion on plastic film or metallic foil at pre-treatment stage before printing, laminating or coating takes place. As one of sophisticated corona treater supplier in America, ISI has abundant experience and know how to help you to avoid the adhesive issue when selecting the corona plasma equipment, we can assist you to measure surface tension accurately and consistently among different plastic materials, and also we will help you to clarify the gettability gap for the material that you are about for applying the proper power density.

Quality and Reliable Turret Winder Recommended

Leave a Comment

Quality and Reliable Turret Winder Recommended

The Design of Turret Winder

Turret winders typically are designed to small to medium sized batches of rolls of materials including flexible packaging, tape, paper, plastic film, and nonwovens from a continuously moving web. The turret winder ISI provided is advances in web positioning, tension control and rewind shaft technology, we optimize these different processes in turret winder to create several advantages such as no fold-over, tapeless transfers which enables center-wind turrets to deliver high-quality finished rolls for a broad variety of applications.

Quality and Reliable Turret Winder Recommended

Dual Turret Winder

The Dual Turret Winder ISI provided can be custom designed to enable our clients to operate several genres of product of different material , thickness, speed, width and roll diameter to allow versatility for their production system. The Model 972D Dual Turret winder is a capital investment that guarantees you Quality and Reliability. Improve your productivity as well as lower scrap rates and downtime.

Single Turret Winder

If you are looking for a Reliable Single Turret Winder with the most reasonable price, than your are come to the right place! The Single Turret Winder ISI provided is able to handle diverse materials with automatic roll change function. Simplicity design and friendly operating interface make our Single Turret Winder can be your smartest investment ever! The model 972S Single Turret Winder gives you the things you want the most…. Speed and Reliability. Improve your productivity as well as lower scrap rates and downtime.

Using the Corona Electrostatic Treater to Improve Filtration Effiency in Face Masks

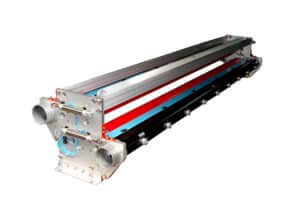

Leave a CommentDo you ever wonder how a face mask works? The heart of a face mask is a melt-blown, non-woven polypropylene (PP) material which is inserted into the filter layer of a surgical mask. The fiber diameter of this PP material is only about one thirtieth of a human hair, or about 6µm. However, this in itself, does not make the masks effective. The filtration efficiency of the material can be further improved by treating it with an electrostatic field, creating what is called an “electret material”. With this added electrostatic process, the average diameter of the PP material’s fibers can be reduced ten times, resulting in diameters as fine as 600nm and filter efficiencies of over 99%. According to current evidence, the COVID-19 virus is primarily transmitted between people with small virus droplets around 5-10μm in diameter. While wearing a mask, a virus droplet is captured by the added static electricity in the electret material and is absorbed on the mask surface, making these electrostatic-assisted mask materials highly effective in preventing the virus droplet from getting past the mask.

CORONA ELECTROSTATIC TREATMENT is the process that creates this “electret material”, which is the critical filter component in face masks. The Corona Treater equipment includes a high frequency inverter power supply, special electrodes, and rollers. It works by applying a high voltage corona discharge to the material at high temperature. Materials treated with the Corona Electrostatic Treaters increases the material’s ability to retain charge for extremely long periods of time. Contact us for additional information.